Right of Way Headframe

The Right of Way Mine operated for two years, closing in 1909, followed by intermittent reactivation for the next 78 years. From 1906 to 1935, 2,969,205 ounces of silver were produced at this site.

Cobalt Lake

Nipissing High Grade Mill

These ruins are the remains of the high-grade mill site. It recieved concentrated material from the low grade mill as well as high grade ores from the mine sites. High Grade refers to ore above 1000 ounces per ton. Here, it was processed with cyanide and sent to a refinery. The mill operated between 1911 to 1918, and ultimately recovered 29.6 million ounces of silver.

Cobalt Lake Tailings

Cobalt Lake has been drained and re-flooded several times in order to extract ore from below the lake, to store tailings or waste rock, and for re-processing those tailings to extract any residual silver.

Silver

Silver is mainly used for jewelry, silverware, in photographic paper and film, in solder, mirrors, dental work, coins, and medallions. About 12.6 million grams, or 445 million ounces were produced in the area since it's discovery in 1903.

Cobalt

Cobalt is used in alloys for jet engines and gas turbines, powerful magnetic steels, and some types of stainless steels, blue pigments in paint, porcelain, glass etc.

Nipissing Hill

The hill around you is bare because the entire slope was deforested and power-washed in 1914 during exploration of the ore zone.

Native Silver

"Native" refers to silver that occurs in a metallic form, and not bound within minerals. It is howver found with other sulphide and arsenide minerals.

Cobalt Bloom

Because this was the high-grade mill, it's easy to find brightly coloured Cobalt minerals laying on the ground. This "Cobalt Bloom" is what first alerted prospectors to the potential presence of more valuable metals. The fuschia colour could be the mineral Erythrite.

Ruined Structures

McKinley-Darragh Mill

Just a few minutes away, you can visit another set of ruins, this time of the McKinley-Darragh Mill. James McKinley and Ernest Darragh were the collecting timber when they came across glittering rocks on the south shore of Cobalt Lake. It contained 400 ounces of silver per ton and led to the development of the McKinley Darragh mine. That mine produced over 20 million ounces of silver in the first sixteen years of operation.

Looking Forward

Today, some exploration is coming back to the Cobalt region, but this time, prospectors are looking for cobalt itself which is quickly become a crucial metal for many modern technologies and is currently almost entirely imported from the politically unstable the Democratic Republic of Congo.

Little Silver Vein

Silver, along with cobalt, nicel, and arsenic is hosted in calcite veins. This vein was discovered in 1903 by French Canadian Tom Hebert. Aaveraged 20 cm in width, and yielded over 700,00 ounces of silver by 1932, for a 1986 value of $4,760000.

Aerial Tramway

An aerial tramway once delivered ore from Nipissing #73 shaft in the centre of town to the low grade mill.

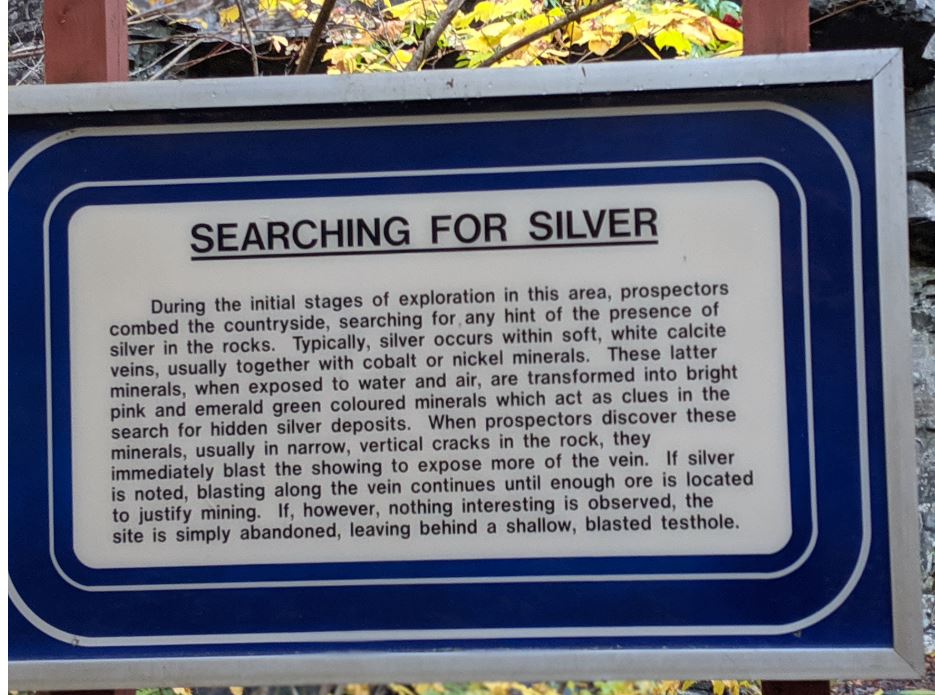

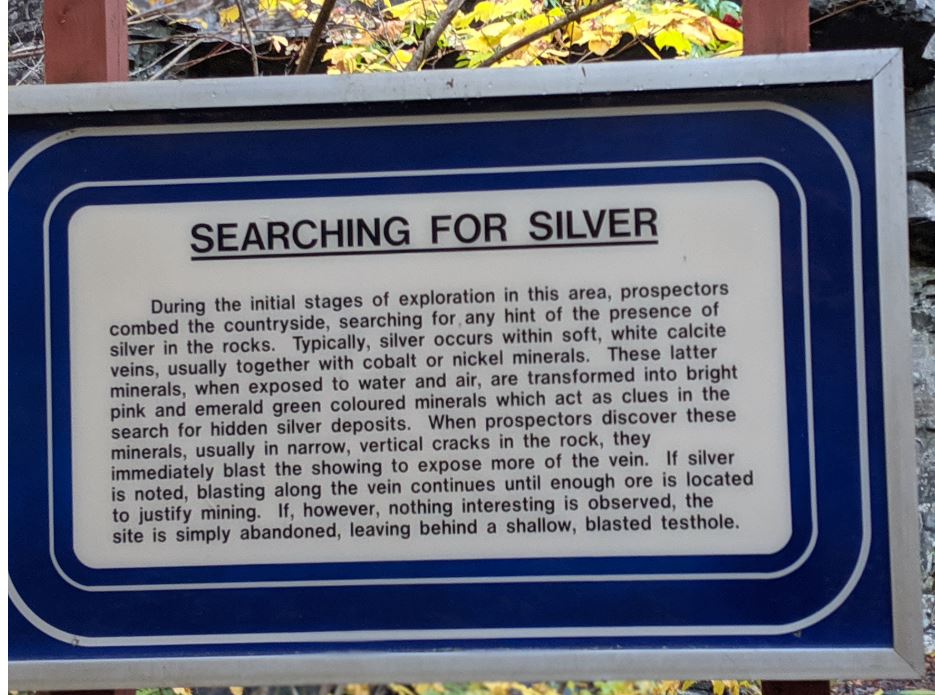

Searching for Silver

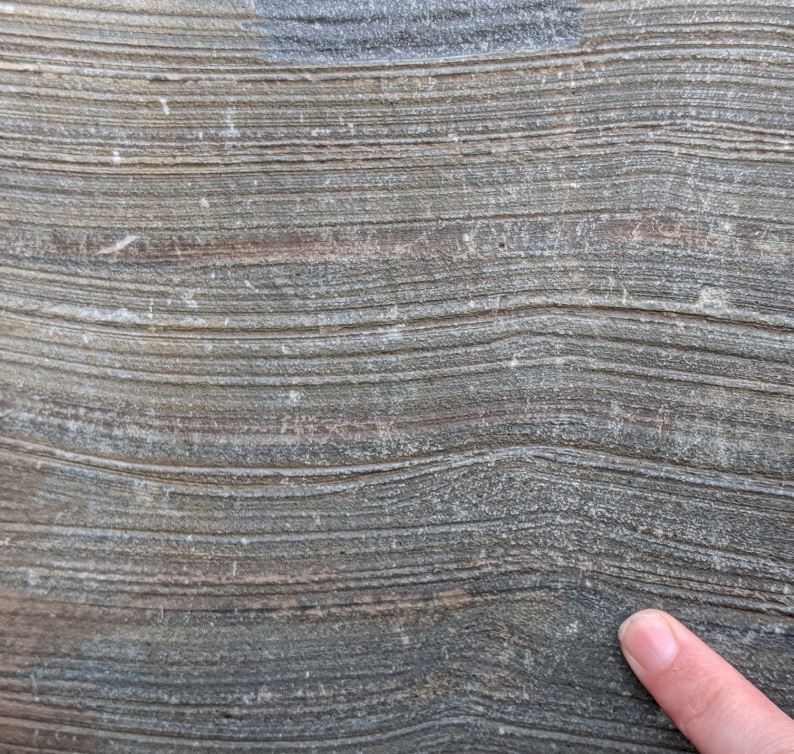

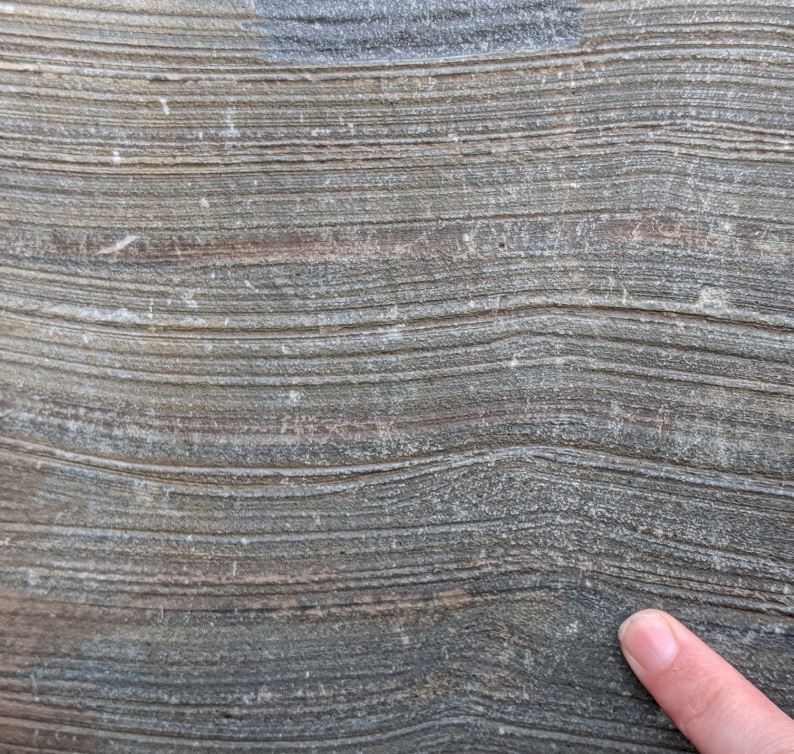

Ancient Ripples

The host rock to the mineralization is made of delicately laminated siltstones of the Gowganda Formation. These were probably deposited in a broad delta.

Metal headframe in centre of town

The metal headframe in the town centre Is the Millet Green Miller Memorial Site, and also serves as the Cobalt Historical Society Office. Miller was the first Provincial Geologist for Ontario, and was in power during the Silver Rush. He gave Cobalt it's name.

Open Pit Mine

This is a great example of open-pit mining where ore is extracted from the top-down.

Scale of Workings

Over 155 major silver veins were discovered and mined from 18 working shafts with 45 miles of underground workings.

Heritage Silver Trail

The Heritage Silver Trail is a self-guided tour around 19 sites of historical significance. It is well worth the time while visiting the town!

Nipissing Hill

Nipissing Hill where large-scale mining and exploration were done is visible as this bare patch.

Mineralization

Silver in the Cobalt Region was formed about 2.2 billion years ago when mafic igneous intrusions of diabase were injected through the sedimentary rocks of the Huronian Supergroup. The hot magma caused fluids rich in calcium carbonate, silver, and other metals to circulate and concentrate the metals in cracks within the host rock.

Cart Lake

Cart Lake has been the dumping ground for rock-waste from mining operations since 1910 and currently holds many of the tailings that were considered to be too enriched in cyanide for disposal in Cobalt Lake. From the 1960's until 1983, a flotation mill for separating the desired minerals from a crushed rock slurry operated on the lake and disposed its waste directly into the waters. Cart Lake is now almost completely filled in and is slowly becoming revegetated.

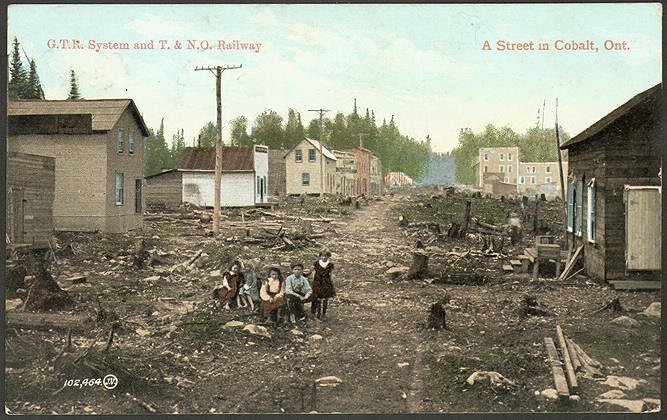

The Birthplace of Hard Rock Mining

Cobalt is often considered to be the birthplace of hard-rock mining in Canada. Unlike placer mining where metals are held in soft surface sediments, extracting minerals from "hard rocks" required capital (investment) to develop mining infrastructure. The international investments attracted by the boom in Cobalt translated to increased exploration throughout the Canadian Shield. In total, the Cobalt camps produced over 460 million ounces of the metal between 1907 and the 1990's when most production had ceased.

Right of Way Mine Site

A headframe is a building that houses the machinery for hoisting materials in and out of a mine shaft.

Townsite #1 Shaft

The first underground mine shaft was sunk down in 1907 at the Townsite Mine. The remaining tower structure is called a headframe and is built directly above the main mine shaft in order to house the equipment that would hoist ore and other materials up and down the 320 foot pit. Here, silver-rich minerals are concentrated in a vein that was formed some 2.2 billion years ago when hot, mineral rich fluids where driven under high pressure into the surrounding rock.

1903: The Discovery

The discovery of silver in the Cobalt Region in 1903 can be directly credited to efforts made by the provincial government to colonize the north by construction of the Temiskamig and Northern Ontairo Railway. Two railway workers, James McKinley and Ernest Darragh noticed an odd pink stain on the rocks, which was determined by chemical analyses to be "cobalt bloom", a hydrated cobalt arsenate mineral commonly associated with native silver.

Baseball Diamond

The low-lying area in the middle of Cobalt Lake, now used as a baseball diamond, was created by the collection of mine tailings from around the city. It is estimated that more than 300,000 tons of tailings are held within the lake.

Low Grade Mill

The low-grade mill recieved ore that contained less than 100 ounces per ton of silver. Once concentrated, was sent to high grade mill for further refinement.

Cobalt Railway Station

This station, colloquially known as the Millionaires Express carried investors to the Cobalt Camp.

Headframe of the Right of Way Mine

A "headframe" is a building that contained the equipment to hoist supplies up and down the shaft.

Little Nipissing Silver Mine

At the Little Nipissing Silver Mine, a consipicuous 20 cm wide void cuts through the 20 metre high rock face where the "Little Silver Vein" was mined out over 100 years ago. Timbers from the original mine workings, used to support the walls and to prevent them from collapsing inwards can be seen within. This mine produced 700 000 ounces of native silver.

Nipissing 81 Mine

The Nipissing 81 Mine Site provides one of the best views of an open pit mining operation and the enormous gash left behind when a vein is mined out.

The White Pine Line

Look around and you will see several giant White Pine trees. Here at Cobalt, we are near the northern-most extent of their range. The White Pine can be identified by their needles which grow in clusters of five.

Larose Blacksmith Shop

Alfred Larose was a blacksmith who is credited as one of the first people to discover silver in the Cobalt area.

1932 downturn

The Boom Town of the 1910's took a downturn in the 1930's due to greatly reduced silver prices and lack of new discoveries.

Cobalt Lake Mine

Blasting in 1932 broke through the bedrock cap, causing 400,000 tons of mill tailings to pour into the mine.

Ripple Tops

On bedding surfaces, we can see the actual shape of the ripples, just like what we would see on the seafloor today.

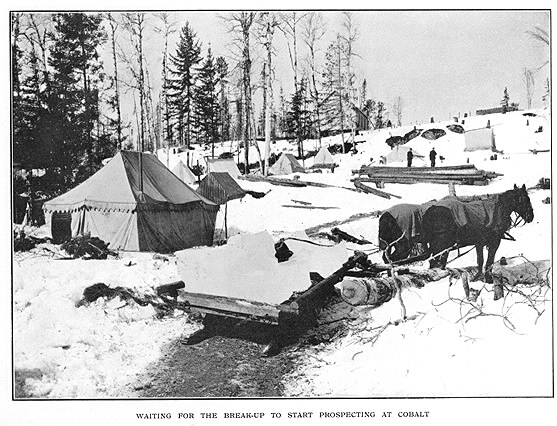

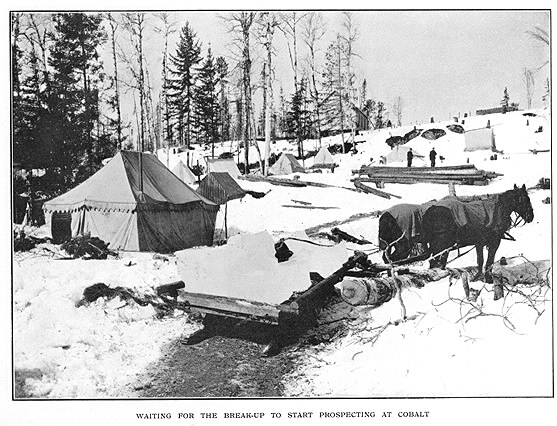

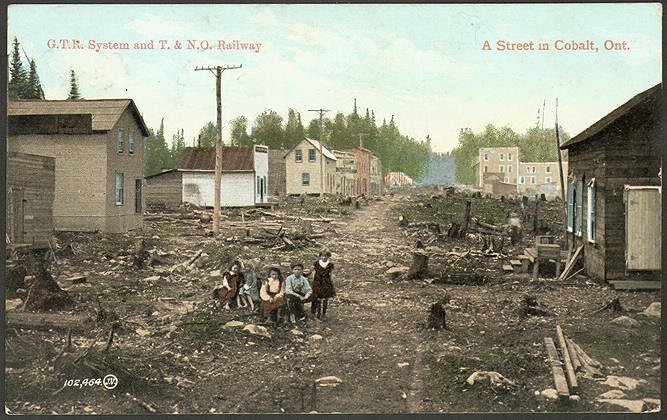

nan

The history of Cobalt is rife with tales of discovery and wealth, but also with fire, disaster, and disease. The rushed pace of the mining boom did not offer adequate time for the Silver City to plan for its many residents. In the early days, there was no clean water supply or sewer systems. Prospectors lived in tents, and later, miners lived in slums. Sewage and garbage was discharged, along with mine tailings, into Lake Cobalt. Mining activities within the town created many hazards. In one case, a dynamite explosion started a fire that destroyed many buildings. Outbreaks of smallpox, and typhoid were caused by poor living conditions. Abandoned mines and mill sites now lay in ruin.

Tailings

Tailings are the waste rock of the mining process. They can be heavily contaminated by metals and chemicals, and often pose a serious environmental risk. They often still contain some small amount of silver, and in some cases can be re-mined years later as technology improves or when metals become more valuable. In the case of the Low Grade Mill, between 80-97% of the silver recovered was recovered.

Hazards

Over 155 major silver veins were discovered and mined from 18 working shafts with 45 miles of underground workings. These underground and openpit workings present a significant hazard and many have been cordoned off by fencing. Chemicals in the tailings also present a hazard.

Miners

Adit

An "adit" is a small horizontal tunnel or passage into a mine. It is used for access and ventilation.

Arsenic

Arsenic is naturally associated with silver. During milling, rocks are crushed, which allows the arsenic in the leftover waste-rock to interact with rainwater and groundwater. Concentrations in surface waters well exceed what would be a natural background level. These contaminants are slowly migrating downstream to lakes that were previously uncontaminated like nearby Kirk Lake. However, the contaminants could be contained by passage through wetlands or by increasing natural or artificial cover.

Machinery

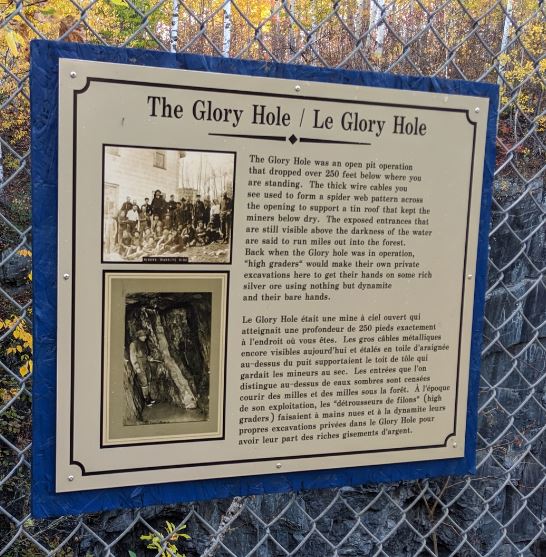

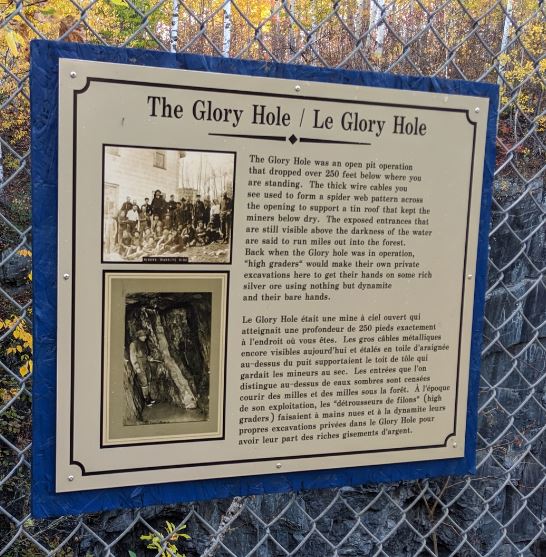

The Glory Hole

The Glory Hole was an open pit mine that dropped over 250 feet below below the surface. A web of cables across the opening supported a tin roof to keep the miners dry.